A metallurgical solution smiLLe™ to achieve a Safer operation and a shorter, simpler turnaround for your Unicracking™Unionfining™ and Oleflex™

What is smiLLe™ ?

The smiLLe™ Alliance

A business alliance between Honeywell UOP, NIPPON STEEL, Mitsui & Co., Ltd was initiated in 2012 to provide a PTA SCC solution to the market.

- NSC has developed the 347AP metallurgy and registered the metallurgy in Codes & Standards.

- UOP has approved that 347AP is the only metallurgical solution to prevent PTA SCC without PWHT, without thermal stabilized heat treatment and without neutralization in hydrocracking and hydrotreating units and so specified smiLLe™ products as option in Schedule A new unit design of hydrocracking and hydrotreating.

- Mitsui has assured the Supply-ability to the market with smiLLe™ products which are made from 347AP metallurgy and cover all products required to assure Anti-PTA SCC efficacy in hydrocracking and hydrotreating units.

A metallurgical solution smiLLe™ to achieve a Safer operation and a shorter, simpler turnaround for your Unicracking™ Unionfining™ and Oleflex™

A proven steel designed to benefit your operation by eliminating all chances of Polythionic Acid Stress Corrosion Cracking cutting your turnaround downtime as Neutralization will not be required.

Safer

A safer unit operation by eliminating all chances of Polythionic Acid Stress Corrosion Cracking.

A safer turnaround by eliminating the usage of Soda Ash.

Shorter

A shorter turnaround without Soda Ash Washing and Nitrogen Purge.

A shorter fabrication and installation period without PWHT and less weld repairs.

Simpler

A simpler turnaround without preparation of Soda Ash Washing, Nitrogen Purge and spent Soda Ash Disposal.

A simpler fabrication and installation without preparation for PWHT

The smiLLe™ Alliance

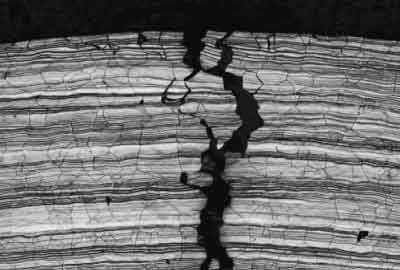

Polythionic Acid Stress Corrosion Cracking occurs on Hydrocracking Units and Hydrotreating Units of petroleum refineries.

Exposure to oxygen and water during turn around forms Polythionic Acid and that leads to PTA SCC on sensitized stainless steel, where soda ash washing, nitrogen purge and PWHT is required as a NACE countermeasure. Sensitized microstructure will not form on the NSC developed 347AP material therefore soda ash washing, nitrogen purge and PWHT will not be required which will enable faster fabrication and construction and shorter turnarounds.

smiLLe™ is a trade mark owned by Mitsui & Co.,Ltd which will be applied to all 347AP products required to assure Anti-PTA SCC effect in Hydrocracking Units, Hydrotreating Units.

[The material features are]

- High sensitization resistance with excellent PTA SCC free feature superior to TP347LN/TP347/TP321.

- Excellent weldability better than TP347/TP321 minimizing welding repairs.

- High creep properties equivalent to TP347

- High resistance on Stress Relaxation Cracking better than TP347H and as well as TP304H under the design temperature of Hydroprocessing Unit.

The smiLLe™ Supply-ability

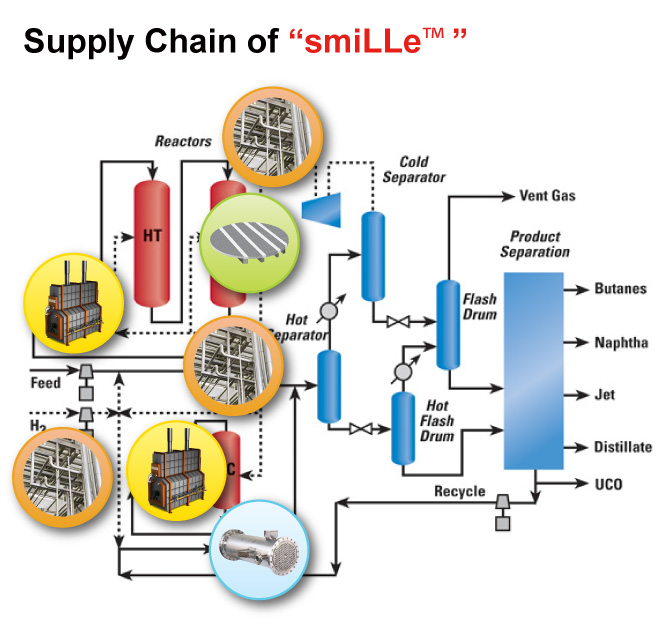

The various materials that would be involved in the fabrication of components requiring austenitic material in hydrocracking and hydrotreating units including Piping, Heater tubes , Flanges, Plate, internal screen for reactor internal fabrication, Weld overlay (lining) for reactor vessel and exchangers, Block valve and control valve bodies can be supplied in smiLLe™ through a network of suppliers, who have been certified by MITSUI & Co.

The Supply Reference

NSC`s 347AP material was introduced to Japanese refineries in 1985 to comply with Japanese strict regulation for sulfur content of fuel oil and were applied to Charge Heaters, Heat Exchangers and Piping of 19 units of Hydrotreating or Hydrocracking by 5 major refineries in Japan. No issue was identified during the 30 years of operational life.

Also several evaluation tests were applied on the actual used tubes in one of the referred refinery and excellent resistance to PTA-SCC was observed. In addition, 347AP was qualified and applied to Heater tubes of Hydrotreating Units, Hydrocracking Units and Delayed Coker at several North American Refineries since 2012.